Impilo yesevisi yeshubhu yokushisa kuhhavini yinde kakhulu, impilo yesevisi yokuklama jikelele amahora angu-20,000, i-220V yensimbi engagqwali yokushisa kagesi ishubhu iyithubhu yensimbi njengegobolondo, eduze nokusabalalisa kwe-axial ephakathi kwe-spiral electrothermal alloy wire (i-nickel chromium, i-iron chromium alloy) igebe layo eligcwele i-iron chromium alloy, i-alloy ye-iron chromium) noma uphawu lwe-ceramic. Ipayipi yokushisa kagesi engu-220V yensimbi engagqwali iyisici esikhethekile sikagesi esiguqula amandla kagesi abe amandla okushisa, ngenxa yentengo eshibhile, kulula ukuyisebenzisa, kulula ukuyifaka, akukho ukungcola, isetshenziswa kabanzi ezikhathini ezihlukahlukene zokushisa.

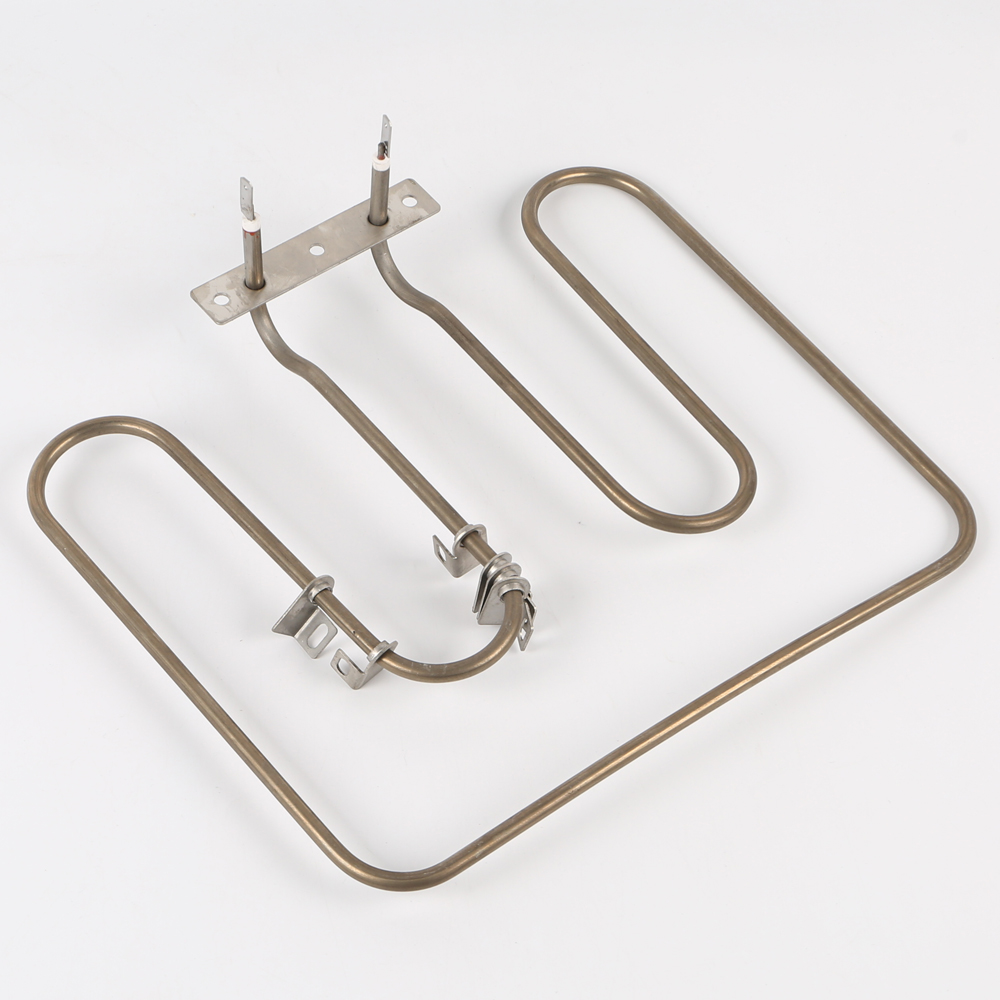

I-1.220V yensimbi engagqwali kagesi yokufudumeza ishubhu iyishubhu lensimbi njengegobolondo, eduze nokusatshalaliswa kwe-axial okuphakathi kwe-spiral electrothermal alloy wire (nickel chromium, iron chromium alloy), isikhala esigcwele ukwahlukanisa okuhle kanye nokuhanjiswa okushisayo kwe-magnesium oxide, iziphetho ezimbili zepayipi eline-silicone noma i-ceramic moold yensimbi yokushisa ehlukahlukene kanye nesici sokushisa sensimbi ehlukahlukene uketshezi. Intambo ye-anode yokushisa ephezulu isatshalaliswa ngokulinganayo kushubhu engenamthungo yensimbi engagqwali ekwazi ukumelana nokushisa okuphezulu, futhi i-crystalline magnesium oxide powder ene-conductivity enhle eshisayo kanye nezakhiwo zokuvikela igcwaliswa ngokuminyene engxenyeni engenalutho. Lesi sakhiwo asithuthuki nje kuphela, kodwa futhi sinokusebenza kahle kokushisa okuphezulu nokushisa okufanayo. Uma kukhona okwamanje ocingweni lwe-anode lokushisa eliphezulu, ukushisa okukhiqizwayo kusakazwa phezulu kweshubhu lensimbi nge-crystalline magnesium oxide powder. Bese idluliselwa ezingxenyeni ezishisayo noma emoyeni ukuze kuzuzwe inhloso yokushisa.

2. Usayizi omncane namandla amakhulu: isifudumezi sikagesi sisebenzisa ikakhulukazi izakhi zokushisa ze-tubula zeqoqo ngaphakathi, futhi isici ngasinye sokushisa se-tubula yeqoqo sinamandla angu-5000KW.

3. Ukusabela okusheshayo okushisayo, ukunemba kokulawula izinga lokushisa eliphezulu, ukusebenza kahle okuphezulu kokushisa okubanzi.

4. Ububanzi besicelo esibanzi, ukuguquguquka okuqinile: i-heater ejikelezayo ingasetshenziswa ezenzakalweni zokuvimbela ukuqhuma noma ezivamile, izinga layo lokuvikela ukuqhuma lingafinyelela ku-B no-C, futhi ukucindezela kwayo kungafinyelela ku-10Mpa. Isilinda singafakwa sibheke phezulu noma sivundlile ngokuya ngezidingo zabasebenzisi.

5. Ukushisa okuphezulu kokushisa: ukushisa okusebenzayo kokuklama kwe-heater kungafinyelela ku-850 ° C, okungatholakali kuma-heat exchangers jikelele.

6. Ukulawula okuzenzakalelayo okugcwele: Ngomklamo wesekethe ye-heater, ingakwazi ukubona kalula ukulawulwa okuzenzakalelayo kwezinga lokushisa lokuphuma, ingcindezi, ukugeleza namanye amapharamitha, futhi ingaxhunyaniswa nekhompyutha ukuze kuzuzwe inkhulumomphendvulwano yomshini womuntu.

7. Ukuphila isikhathi eside, ukuthembeka okuphezulu: i-heater yenziwe ngezinto ezikhethekile zokushisa kagesi, futhi umthwalo wamandla wokuklama unengqondo, i-heater isebenzisa ukuvikelwa okuningi, okwenza ukuzinza nokuphila kwe-heater kukhule kakhulu.

| Umgodla Wethusi | Ukushisisa amanzi, izixazululo zamanzi ezingagqwali ethusi. |

| Umgodla we-stell ongenasici | Ukusebenzisa itiyela netiyela, izindawo zokugeza zikasawoti ezincibilikisiwe, izinto zokuhlanza i-alkaline, nokucwiliswa emafutheni. Kanye nokuphonsa ku-aluminium kanye nokubopha ezindaweni zensimbi. Izisetshenziswa zokucubungula ukudla, uketshezi olubolayo. Impahla ejwayelekile insimbi engagqwali 304. |

| I-Incoloy Sheath | Ukushisa okuvela emoyeni, ukushisa okuvela phezulu, izinto zokuhlanza nezokukhipha amafutha, izixazululo zokukhetha nokucwenga, nezinto ezonakalisayo. Kumazinga okushisa aphezulu, ngokuvamile. |

| i-itanium tube | indawo edlayo. |

Ihhavini kagesi, okokusebenza kwamakhemikhali, ukwakhiwa kwepulasitiki nezinto ezisizayo, umshini wokucindezela oshisayo, umshini kagwayi, umshini wokuvala ngokushesha, umshini wokwenza imithi, okokusebenza kwe-sauna, isifudumezi samanzi kagesi, izinto zasekhishini, izinto zokuhlanza ezimbonini, okomoya okuhweba kanye nemishini yamanzi okuphuza, okokusebenza kwamandla elanga, okokuthosa ngogesi, i-wave soldering emshinini wokushisa we-electronic automation, i-castectic be-diethi ye-electronic automation equipment, i-semicondud be-die Izingxenye zemishini yokushisisa yomjovo, ipulasitiki, ukudla, ezokwelashwa, izindwangu, i-petroleum, imishini, i-electroplating, ukupakisha nezinye izimboni.