| Igama lomkhiqizo | I-Defrost Tubular heater |

| I-Humidity State Insulation Resistance | ≥200MΩ |

| Ngemuva kwe-Humid Heat Test Insulation Resistance | ≥30MΩ |

| Ukuvuza Kwesimo Somswakama Kwamanje | ≤0.1mA |

| Ububanzi beshubhu | 6.5mm, 8.0mm, 10.7mm njll. |

| Amandla | 300-400W imitha ngayinye |

| Ubude | Ngokwezifiso |

| I-voltage engazweli emanzini | 2,000V/min (izinga lokushisa elivamile lamanzi) |

| Ukumelana ne-insulated emanzini | 750MOhm |

| Sebenzisa | I-Defrost Heating Element |

| I-tube material | I-SS304,SS316 |

| Isigaba sokuvikela | IP00 |

| Izimvume | CE/CQC |

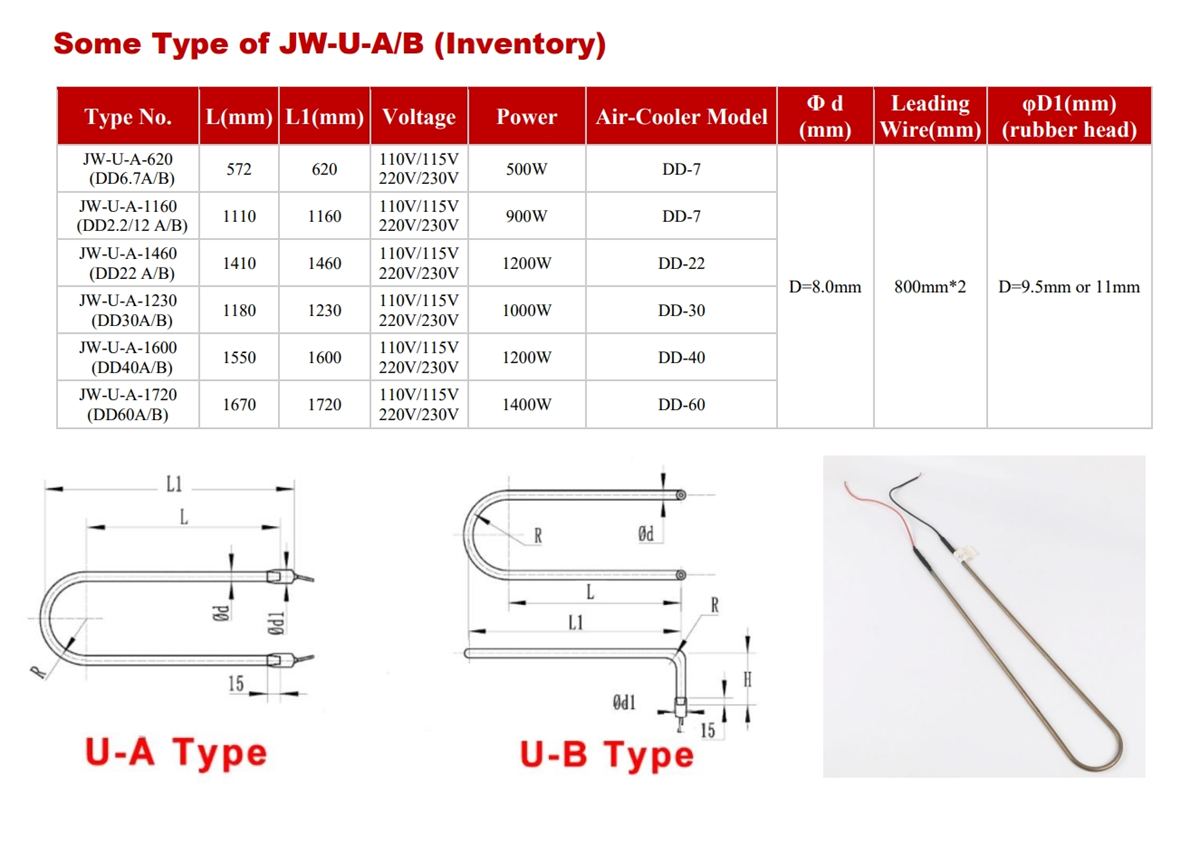

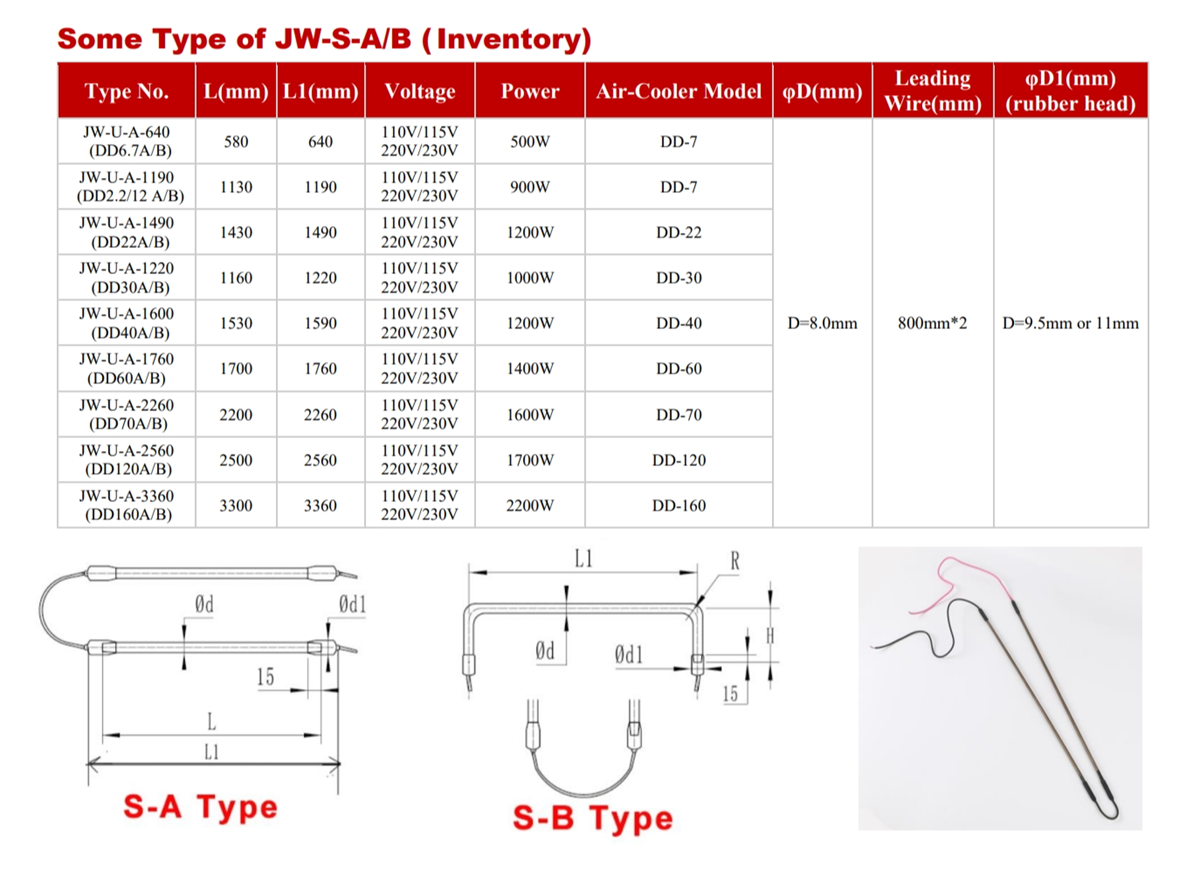

| Umumo, usayizi, amandla/i-voltage ye-defrost tubular heater kanye nobude bentambo eholayo kungenziwa ngendlela oyifisayo njengezidingo zekhasimende, ayikho indinganiso esitokweni sethu futhi idinga ukwenziwa ngendlela oyifisayo lapho ufaka i-oda. Ishubhu yokushisisa i-defrost icishe ibe ngu-300-400W imitha ngayinye yokuncibilikisa, ukwakheka kwe-heater ye-defrsot sinomumo oqondile, u-U, uhlobo lwe-AA nokunye ukuma kwe-spcial. | |

Izinga lokushisa elingaphezulu elivunyelwe izinto ezihlukene zamapayipi akufani, njenge-304 insimbi engagqwali 450-500 degrees, 321 insimbi engagqwali 700 degrees ngezansi, 310S insimbi engagqwali 900 degrees ngezansi; Izinto ezifanayo namandla, izinga lokushisa elihlukile le-medium alifani, amanzi abilayo angama-304 ensimbi engagqwali, izinga lokushisa elingaphezulu kweshubhu elibilisa amanzi licishe libe ngu-106 ° C, futhi izinga lokushisa lomoya wokushisa lingaba ngu-450 ° C, izinga lokushisa le-aluminium yokushisa linconywa ukuthi lisetshenziswe ngaphansi kwama-380 ° C, futhi izinga lokushisa liyi-aluminium ephezulu futhi lincibilike; Ngaphansi kwezinto ezifanayo naphakathi, ithubhu yokushisa kagesi enamandla amakhulu inesivinini sokushisa esisheshayo nokushisa okuphezulu.

Ukucutshungulwa kweshubhu lokushisa kwe-defrost kudinga izinto ezihlanganisa ipayipi lensimbi, i-filler, intambo yokufudumeza kagesi, induku yokuhola, i-glue yokubeka uphawu, intambo yokushisa okuphezulu nokunye. Senza intambo yokumelana ibe yisimo esivunguzayo ngokuya ngomshini wokwenza ucingo olulodwa wokukhiqiza ukuze siqinisekise ibanga lokumayo elilinganayo. Weld induku yokuhola kanye nocingo lokumelana, bese ugcwalisa impushana ye-magnesia ngesigcwalisi. I-tube iyacindezelwa ngemuva kokugcwalisa i-powder. Sisebenzisa umshini wokunciphisa ipayipi ukuze ucindezele futhi wenze, siqinise intambo yokumelana ne-magnesium oxide powder ukuze iminyene, siqinisekise ukuvaleka phakathi kwentambo kagesi yokushisisa nomoya, futhi indawo emaphakathi ayichezuki futhi ithinte udonga lwamapayipi. Bese uyigoba ibe yisimo ikhasimende elisifunayo.

Ngaphambi kophenyo, sicela usithumele imininingwane engezansi:

1. Usithumelela umdwebo noma isithombe sangempela;

2. Usayizi we-heater, amandla kanye ne-voltage;

3. Noma yiziphi izidingo ezikhethekile ze-heater.

Oxhumana nabo: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314