| Indaba Eyinhloko | I-Silicone(V0,V1) kanye nezinketho ze-silicone V0 ezingenisiwe |

| Isilinganiso Sezinga lokushisa | 482°F(250°C)ubuningi bokusebenza |

| Ubukhulu | ngokuvamile 0.03 inch/ 0.75mm (I-Single-Ply), 0.06 intshi / 1.5mm(Dual-Ply),sekela ngokwezifiso |

| Amandla kagesi | Noma iyiphi i-AC noma i-DC (3V-660V), noma i-3phase |

| Ukuminyana kwamandla | Avamile 0.03-0.8watts per square centimeter, ubuningi 3W per square sentimitha |

| Intambo yokuhola amandla | Irabha ye-Silicone, i-SJ Power Cord, noma i-Teflon insulated wire stranded ongakhetha kukho, imvamisa ubude be-100cm noma njengoba iceliwe. |

| Okunamathiselwe | Izingwegwe, ama-eyelets alengayo, Ukulawula izinga lokushisa (Thermostat), |

| Incazelo | 1. I-Silicon Rubber Heating Pad/Ishidi linezinzuzo zokuncipha, ukukhanya, ukunamathela nokuguquguquka. |

| 2. Ingakwazi ukuthuthukisa ukudluliswa kokushisa, ukusheshisa ukufudumala nokunciphisa amandla ngaphansi kwenqubo yokusebenza. | |

| 3. Zishisa ngokushesha futhi zisebenza kahle kakhulu ekuguquleni okushisayo. |

1. Ubuncane, ukukhanya, nokuguquguquka kwezishisi zenjoloba abicah kuyinzuzo;

2. Uma sisetshenziswa, isifudumezi senjoloba ye-silicone singakhuphula ukudluliswa kokushisa, sisheshise ukufudumala, futhi sisebenzise amandla amancane;

3. Ubukhulu bama-heater buqiniswa kusetshenziswa irabha ye-silicone eqiniswe nge-fiberglass;

4. Umthamo omkhulu wamanzi we-silicone ye-rubber heater ngu-1 w/cm2;

5. Izifudumezi zenjoloba ze-silicone zingenziwa ngokwezifiso ngosayizi nokuma.

Izisetshenziswa zokudlulisa ezishisayo

Vimbela ukujiya kwensimbi noma emakhabetheni emoto.

Ukuvimbela ukubanda noma ukuminyanisa ezindlini ezihlala okokusebenza kagesi, njengemishini yokukhipha imali ezenzakalelayo, amaphaneli okulawula izinga lokushisa, igesi noma izindlu zamavalvu okulawula uketshezi, namabhokisi esignali yethrafikhi.

Izindlela zokuhlanganisa ezihlanganisiwe

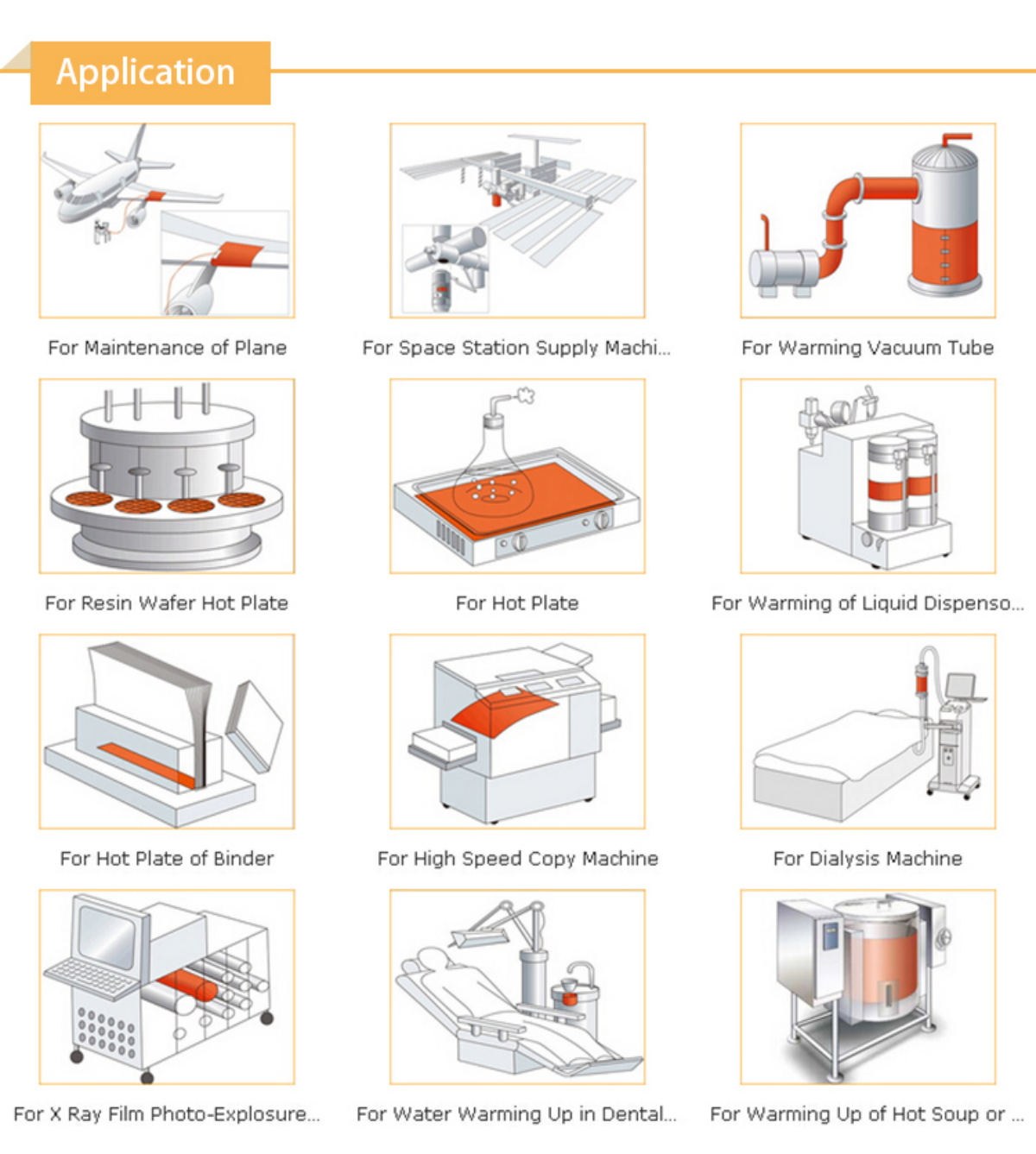

Imboni ye-Aerospace kanye nezifudumezi zenjini yendiza

Izigubhu, eminye imikhumbi, ukulawulwa kwe-viscosity, nokugcinwa kwe-asphalt

Imishini yezokwelapha efana nezifudumezi zamashubhu okuhlola, imishini yokuphefumula yezokwelapha, nezihlaziyo zegazi

Ukulungiswa kwepulasitiki laminated

Izesekeli zekhompyutha ezihlanganisa amaphrinta e-laser nezinto zokukopisha