Uma usebenzisa imishini yokulondoloza umoya obandayo, isiqandisi kanye namakhabhinethi okubonisa isitoreji esibandayo, njll., kuzoba nesenzakalo sokwakheka kwesithwathwa endaweni ye-evaporator. Ngenxa yongqimba lwesithwathwa, isiteshi sokugeleza sizoba mncane, umthamo womoya uzokwehla, futhi ngisho ne-evaporator izovinjelwa ngokuphelele, ivimbele kakhulu ukugeleza komoya. Uma isithwathwa sijiya kakhulu, sizokwenza ukupholisa nokupholisa kwedivayisi yesiqandisi kube kubi kakhulu, kukhuphule ukusetshenziswa kwamandla, futhi ezinye izisetshenziswa zesiqandisi zizosebenzisadefrost heater tubeukuncibilika ngezikhathi ezithile.

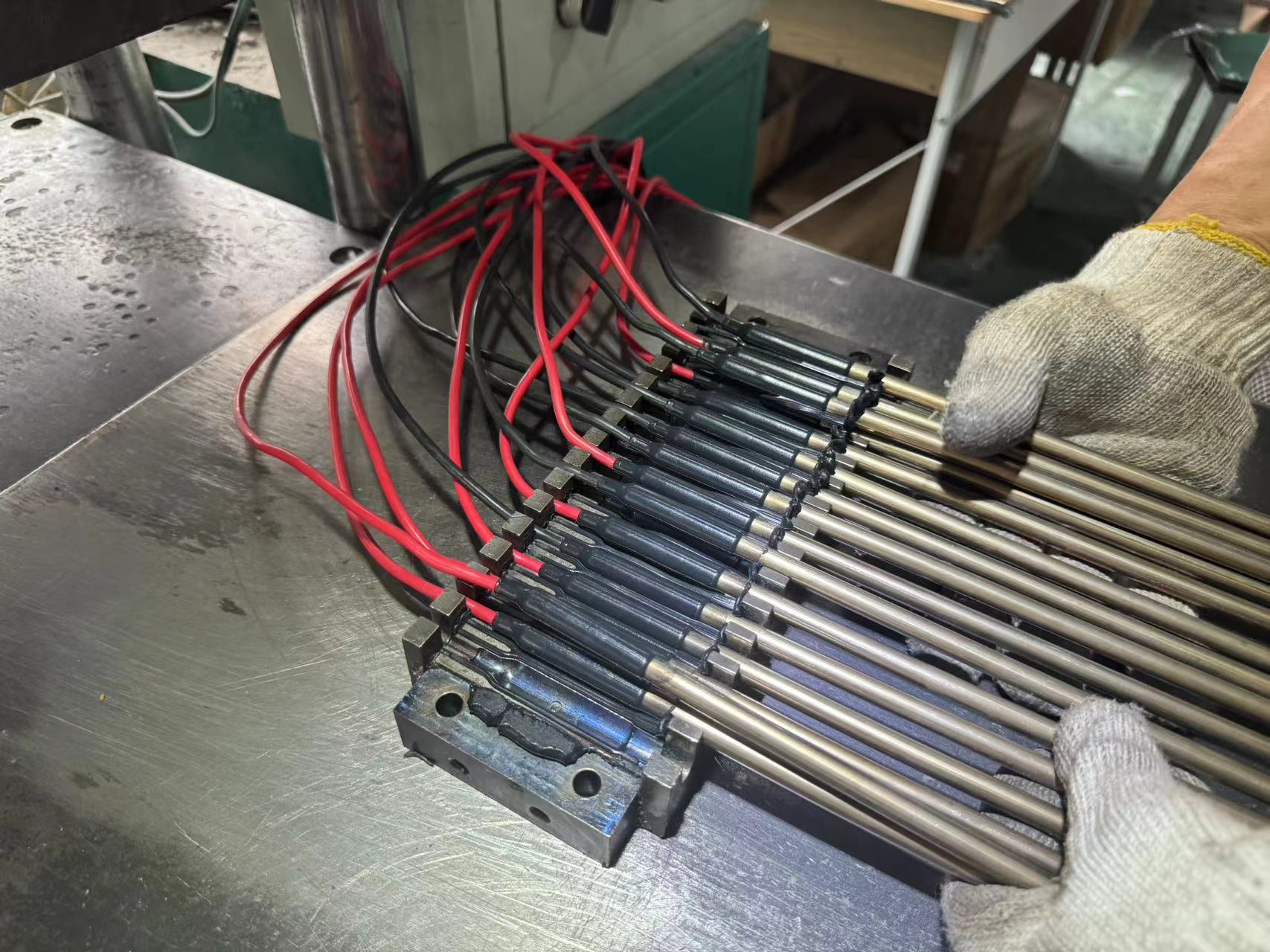

Ishubhu lokushisisa i-electric defrost liyindlela yokuncibilikisa ngokushisisa ungqimba lwesithwathwa olunanyathiselwe phezulu kwempahla kusetshenziswa amashubhu okushisa ahlelwe ngaphakathi kwempahla. Lolu hlobo lweshubhu ye-defrost heater luhlobo lwesici sokushisa sikagesi esimise okwethubhu, esibizwa nangokuthi ishubhu lokushisisa lokuqeda uqhwa noma ishubhu lesifudumezi sokuqeda uqhwa. I-electric defrost heater tube iyisici sokushisa kagesi lapho ithubhu lensimbi lisebenza njengegobolondo, i-alloy heat wire njengento yokushisa, kanye namatheminali okugcina (izintambo) ahlinzekwa. I-insulating medium ye-magnesium oxide powder igcwaliswa ngokuminyene epayipini lensimbi ukuze kulungiswe isici sokushisa.

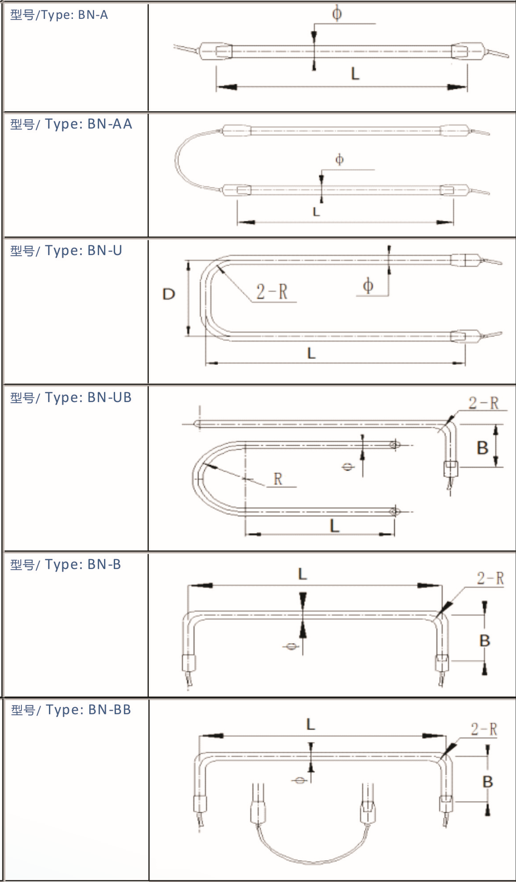

Ngenxa yezimpawu zemishini yokugcina abandayo, njengomswakama ophezulu kanye nezinga lokushisa eliphansi endlini, ukubanda okuvamisile nokushaqeka okushisa,defrosting bafudumale amashubhungokuvamile zisekelwe ezintweni zokushisisa zikagesi ezimise okwethubhu, kusetshenziswa i-magnesium oxide yekhwalithi ephezulu eshintshiwe njengesigcwalisi nensimbi engagqwali njengegobolondo. Ngemuva kokunciphisa, ukuphela kokuxhuma kuvalwe ngesikhunta esikhethekile esicindezelwe yirabha, ukuze ishubhu yokushisa kagesi isetshenziswe ngokujwayelekile emishini yokugcina ebandayo. Ingakwazi ukugoba kunoma yikuphi ukuma ngokuvumelana nezidingo zomsebenzisi futhi ifakwe kalula ezimbanjeni zomshini womoya obandayo noma ngaphezulu kwe-evaporator yekhabhinethi ebandayo noma phansi kwethreyi yokudonsa, njll. Isakhiwo esiyisisekelo se-defrost heaterimi kanje:

a) Induku yokuhola (umugqa) : ixhunywe nomzimba wokushisa, wezingxenye kanye nokunikezwa kwamandla, izingxenye kanye nezingxenye ezixhunywe nezingxenye zensimbi zokuqhuba.

b) Ipayipi legobolondo: ngokuvamile insimbi engagqwali engama-304, ukumelana nokugqwala okuhle.

c) Intambo yokushisisa yangaphakathi: i-nickel chromium alloy resistance wire, noma i- iron chromium aluminium wire material.

d) Imbobo yepayipi yokushisa kagesi ivalwe ngerabha ye-silicone.

Ukuze kuxhunywe ipayipi lokushisa, imodi yokuxhuma yedefrosting electric bafudumale ipayipiibonisa ukuthi u-Y uwukuxhumana okumise okwenkanyezi, u-Y kufanele axhunywe kulayini ophakathi nendawo, futhi lawo angabonisiwe kuwukuxhuma kukanxantathu. Isibonelo, ishubhu ye-defrost heater ye-chiller ngokuvamile ingu-220V, futhi umkhawulo owodwa weshubhu ngalinye le-defrost heater lixhunywe kulayini womlilo, kanti enye ingxenye ixhunywe kulayini ophakathi nendawo. Ngaphezu kwalokho, amandla okufaka amakwe ezindlini zeshubhu yokushisisa ngokuvamile angamandla alinganiselwe weshubhu lokufudumeza.

Indlela kagesi defrosting ilula futhi kulula ukusebenza, kodwa amandla kadefrosting bafudumale tubengokuvamile inkulu, futhi uma ikhwalithi yeshubhu lokushisisa ingeyinhle noma isetshenziswa isikhathi eside, kulula ukuyishisa noma ibangele ngisho nomlilo, ngakho indlela yokuqeda iqhwa ngogesi inezingozi ezinkulu zokuphepha futhi idinga ukuhlolwa njalo. Ishubhu ye-heater ye-defrost ngokuvamile ijwayele ukulimala okulandelayo:

1. Kusukela ekubukeni, kungabonwa ukuthi induku ehamba phambili yonakele, isambatho sensimbi yensimbi sonakalisiwe, i-insulator yonakalisiwe noma uphawu luhluleka.

2, izakhiwo ezingokomzimba nezamakhemikhali zeshubhu lokufudumeza zishintshile futhi azikwazi ukuhlangabezana nezidingo zokusetshenziswa. Isibonelo, eyodwa yalezi zimo ezilandelayo ngeke isakwazi ukusetshenziswa:

① I-voltage yokumelana yeshubhu yokushisisa iphansi kunevelu evamile, inani lamanje lokuvuza likhulu kuno-5mA noma inani lokumelana nokufakwa kwe-insulation lingaphansi kuka-1MΩ

(2) Igobolondo linokukhishwa kwelangabi nezinto ezincibilikisiwe, futhi ingaphezulu ligqwalile kakhulu noma alivunyelwe ukuthi lilungiswe.

③ Amandla wangempela weshubhu yokushisisa adlula amandla alinganiselwe ngo-±10%.

④ Umumo weshubhu lokushisisa ushintshe kakhulu, okuholela ekushunyeni kongqimba lwe-insulation ngokusobala angalingani, futhi ukusebenza kokufakelwa kwehliswa kakhulu ngesilinganiso, esingahlangabezani nezindinganiso ezifanele.

Isikhathi sokuthumela: Nov-19-2024